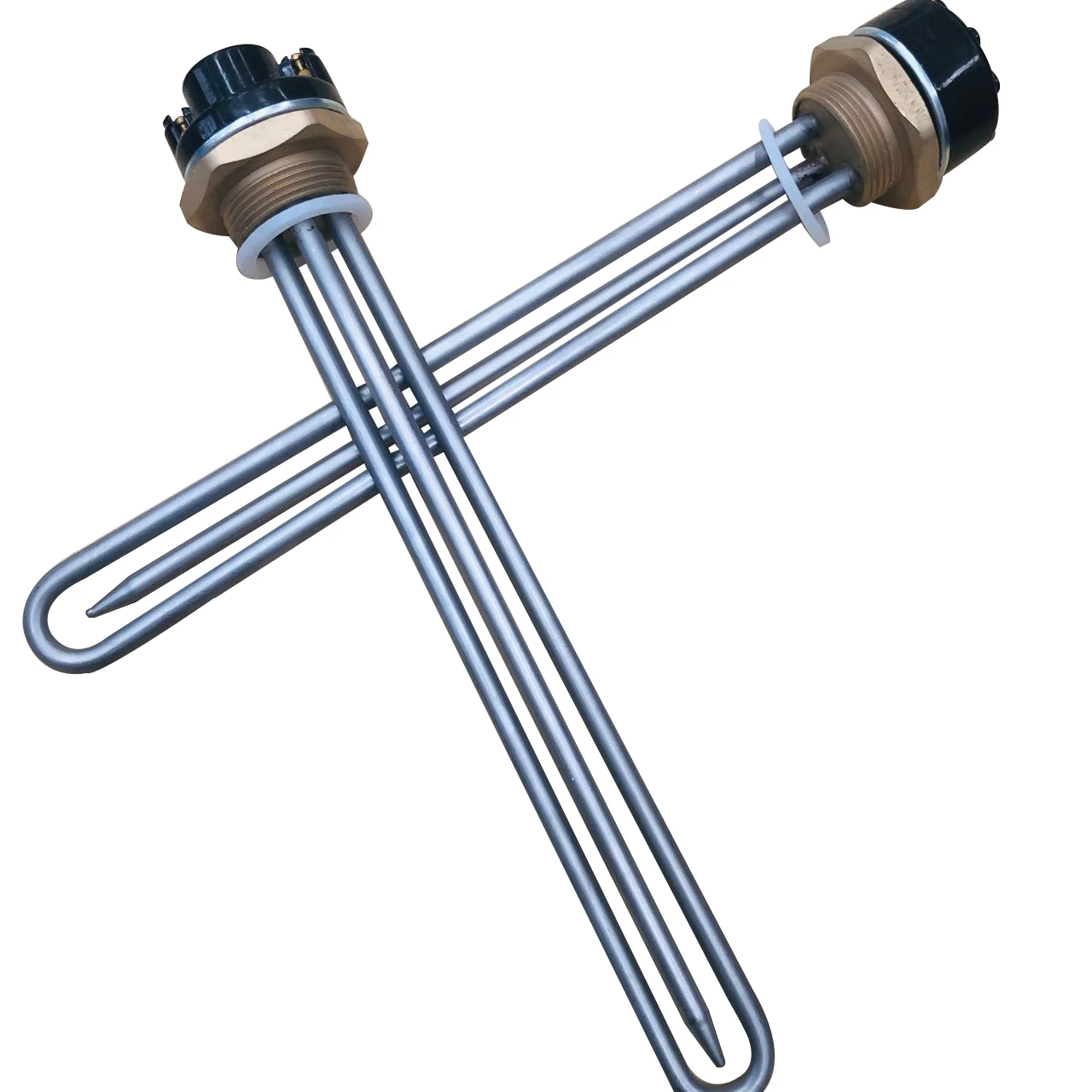

Flange Electric Heater Water Tank Heating Tube For Petroleum Chemical Industry

eBay

Explosion-proof flange immersion heater specification sheet 1

Specifications | Power(KW) | Flanged Immersion Heater For Liquid | Flange Heater For Air | Temperature control range | Power Supply | ||||

Size(mm) | Us(pieces of U) | Size(mm) | Us(pieces of U) | ||||||

XTFL-5 | 5 | DN80*500 | 3 | DN100*600 | 3 | RT-700 | Single-phase 220V | ||

XTFL-10 | 10 | DN80*700 | 3 | DN100*700 | 6 | Three-phase380V,50HZ | |||

XTFL-15 | 15 | DN125*700 | 6 | DN125*700 | 9 | ||||

XTFL-20 | 20 | DN150*800 | 6 | DN150*900 | 9 | ||||

XTFL-30 | 30 | DN150*800 | 9 | DN150*1000 | 12 | ||||

XTFL-40 | 40 | DN200*1000 | 12 | DN200*1200 | 15 | ||||

XTFL-50 | 50 | DN200*1000 | 12 | DN200*1200 | 15 | ||||

XTFL-60 | 60 | DN200*1200 | 15 | DN250*1300 | 18 | ||||

XTFL-80 | 80 | DN250*1400 | 18 | DN250*1500 | 18 | ||||

XTFL-100 | 100 | DN250*1600 | 18 | DN300*1600 | 24 | ||||

XTFL-120 | 120 | DN250*1600 | 18 | DN300*1600 | 27 | ||||

XTFL-150 | 150 | DN300*1600 | 24 | DN350*1600 | 36 | ||||

XTFL-180 | 180 | DN300*1600 | 27 | DN350*1800 | 36 | ||||

XTFL-200 | 200 | DN300*1800 | 27 | DN400*1800 | 45 | ||||

Explosion-proof flange immersion heater specification sheet 2

Specifications | Power(KW) | Flanged Immersion Heater For Liquid | Flange Heater For Air | Temperature control range | Power Supply | ||||

Size(mm) | Us(pieces of U) | Size(mm) | Us(pieces of U) | ||||||

XTFL-240 | 240 | DN350*1800 | 36 | DN400*1800 | 54 | RT-700 | Three-phase380V,50HZ | ||

XTFL-280 | 280 | DN350*1800 | 36 | DN500*1600 | 72 | ||||

XTFL-300 | 300 | DN400*1800 | 42 | DN500*1600 | 72 | ||||

XTFL-360 | 360 | DN400*1800 | 45 | DN500*1800 | 72 | ||||

XTFL-400 | 400 | DN400*1800 | 54 | DN600*1800 | 84 | ||||

XTFL-450 | 450 | DN450*1800 | 60 | DN600*1800 | 90 | ||||

XTFL-500 | 500 | DN500*1800 | 72 | DN700*1800 | 108 | ||||

XTFL-600 | 600 | DN600*1800 | 84 | DN800*1800 | 120 | ||||

XTFL-700 | 700 | DN600*1800 | 90 | DN900*1800 | 144 | ||||

XTFL-800 | 800 | DN700*1800 | 108 | DN900*1800 | 180 | ||||

XTFL-900 | 900 | DN800*1800 | 120 | DN900*1800 | 180 | ||||

XTFL-1000 | 1000 | DN900*1800 | 144 | DN1000*1800 | 216 | ||||

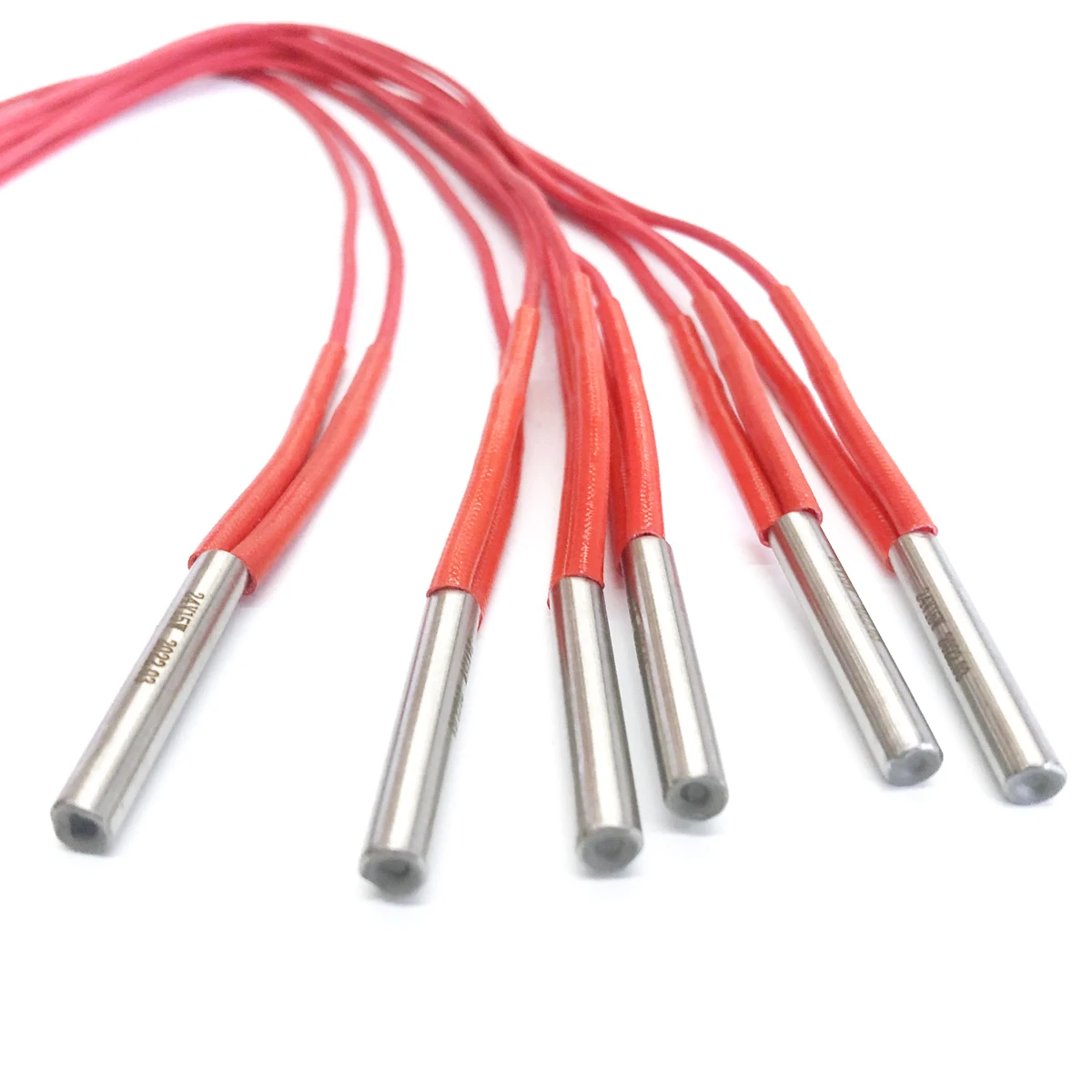

Thread specification | Power/voltage | Pipe diameter | Play the material | length |

DN40 | 220v 3kw | 10mm | 304 stainless steel | 200mm |

DN40 | 220v 4.5kw | 10mm | 304 stainless steel | 230mm |

DN40 | 220v/380v 6kw | 10mm | 304 stainless steel | 250mm |

DN40 | 220v/380v 9kw | 10mm | 304 stainless steel | 300mm |

DN40 | 20v/380v 12kw | 10mm | 304 stainless steel | 350mm |

Application:

1. It is used to dry wood, paper, printing and dyeing, paint residue, etc

2. Melting and heating of nitrates and other salts.

3. Melt low melting alloy, such as tin melting furnace, etc.

4. Building heating.

5. Heat flowing air and still air.

6. Infrared radiation heating device.

7. Low temperature electric furnace, such as industrial electric furnace with air circulation, electric furnace box, etc.

8. Heating device in oil, water and other chemical liquid and electroplating bath solution.

9. Sea water electric distillation unit.

10. Heating device for alkali and acid.

11. In the food industry, it is used to bake all kinds of bread, biscuits and pastries, and it is used as an electric heating device in the water tunnel.

12. Plastic products processing and molding extrusion device and rubber products molding and vulcanization device.

13. In medical and health disinfection equipment, such as sterilizer, sterilizer, etc.

14. Heating and enameled wire drying device of vacuum impregnation equipment of motor, etc.

15. Various household electric appliances in daily life, such as electric stove, electric oven, electric rice cooker, electric frying pan, electric frying pan, water heater, electric iron and other products.

Company Profile

SINTON GROUP was founded in 2001,formerly known as the trade of electric heating and instrumentation, the group's total assets are RMB120 million, with 360 employees. In 2010, we had our own factory building and 5A office production environment, From trade mangement to self-built factory, office building production and sales of explosion-proof heater ,air duct heater,pipeline heater, drying oven, gas mould temperature machine, electromagnetic thermal oil furnace, thermal oil furnace and all kinds of heating elements.From embarrassingly short of money to group mangement model, at present, we integrated research, development, production and sales the products are exported to 12 countries in the world,Mainly Europe and America with strong product independent research and development capabilities and technological innovation. The work has obtained the explosion proof authentication,many patents authentication, the quality system authentication.

Q:What is our competitive advantage?

A:You are ordering directly from the factory.We provide one-stop service, from order taking, customized research and development,

to product follow-up, after-sales, etc. If

you buy our products, we are responsible for you to play the end.

Q: What is the lead time for Heater products?

A: Samples - within 3 working days with materials in stock Mass production - usually 7-14 working days (depends on quantity and

raw material situation, please further discuss with our team. )

Q: What is the MOQ for Heater products?

A: Reheat products produced with common materials can be ordered at 1pcs. If infrequently used materials required, it depends on

the situation of the materials.

Q: Do you manufacture custom parts?

A: Yes. We have thousands of designs in our files of custom heaters and sensors designed for every imaginable application. Our

Sales and Engineering teams are here to help you design a product that fits your needs.

Q: If we have heating projects, how to progress project design or select a product?

A: We have professional sales to provide pre-sale consulting services and engineering team for technical support. Any

questions about products or technical questions please communicate with our sales team and provide specific applications and

requirements.

Related products